Real-time insights for

optimized mineral processing

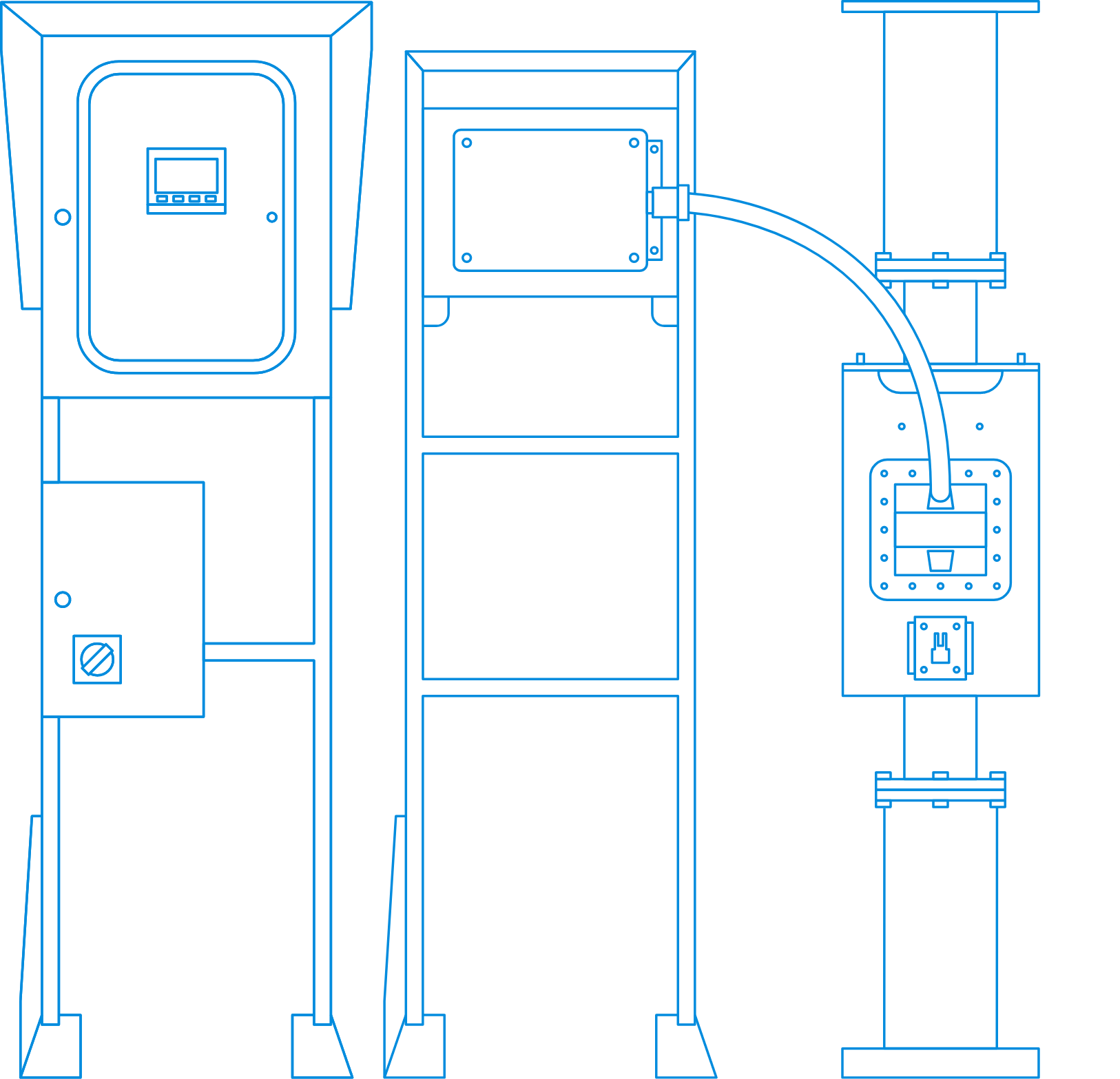

The Blue Cube Dry Analyzer is your ultimate solution for enhancing operational effciency and accuracy in mineral analysis. Designed for in-line installation, it seamlessly integrates into existing processes. This cutting-edge technology provides real-time insights, measuring a wide range of minerals with inherently safe technology.

The Blue Cube Dry Analyzer is used for the in-line measurement of dry free-flowing ore streams with grain sizes below 2mm. The analyzer was specifcally developed for the mineral sands industry, however it can be adapted to other applications.

Draslovka’s unique technology provides multiple measurements with a single instrument. State of the-art spectroscopy and mathematical modelling are used to provide these real-time measurements to enable process control.

In-line measurement

Multiple measurements

Low maintenance

Fast response

Heavy mineral applications

Process

Measure

Measures various parameters such as mineral grade, elemental grade, particle size fraction, and % solids. Measures in-line, continuously, updating every 15 seconds. The Dry Analyzer is installed on pumped, upward-flowing process lines of any diameter greater than 25mm.

Control

Data made available by an the Blue Cube Dry Analyzer on a high tension roll (HTR) separator is an example of real-time control in the mineral sands industry. Through the manipulation of the corona wire high voltage settings, it is possible to control the product grade in real-time.

Optimization

With the availability of the real-time data, it is possible to track the effect of process changes on the grade without full plant surveys. Product grade can be optimized and impurities minimized, all in real-time.

Request a meeting